Que cherchez-vous?

X

Aucun résultat

Recherche en cours ....

Entrez au moins {{MinCars}} caractères

{{result.Name}}

{{result.SubInfo}}

Quelques réalisations

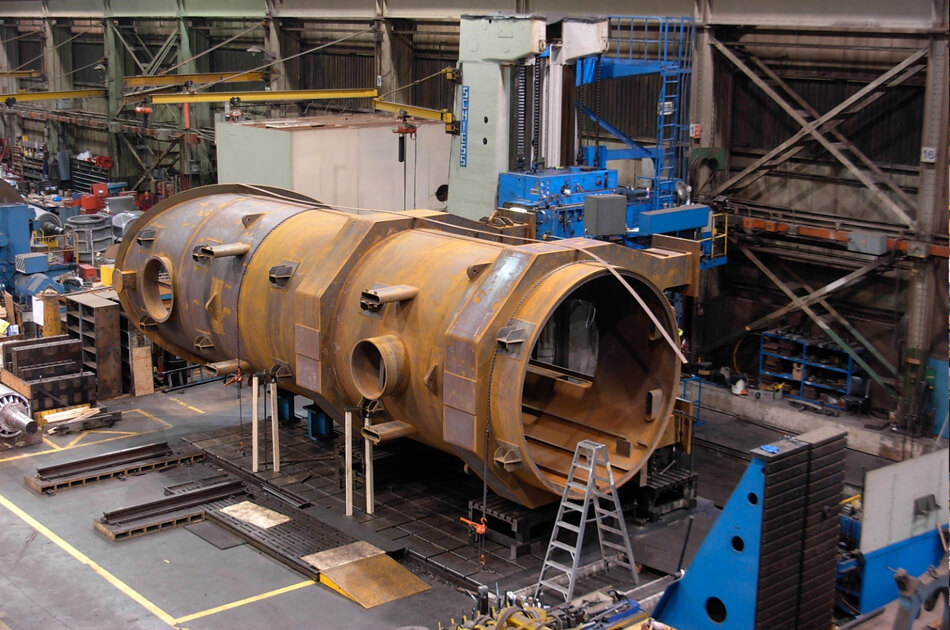

Fabrication et usinage de composantes de four industriel

Usinage de composantes hydrauliques pour secteur automobile

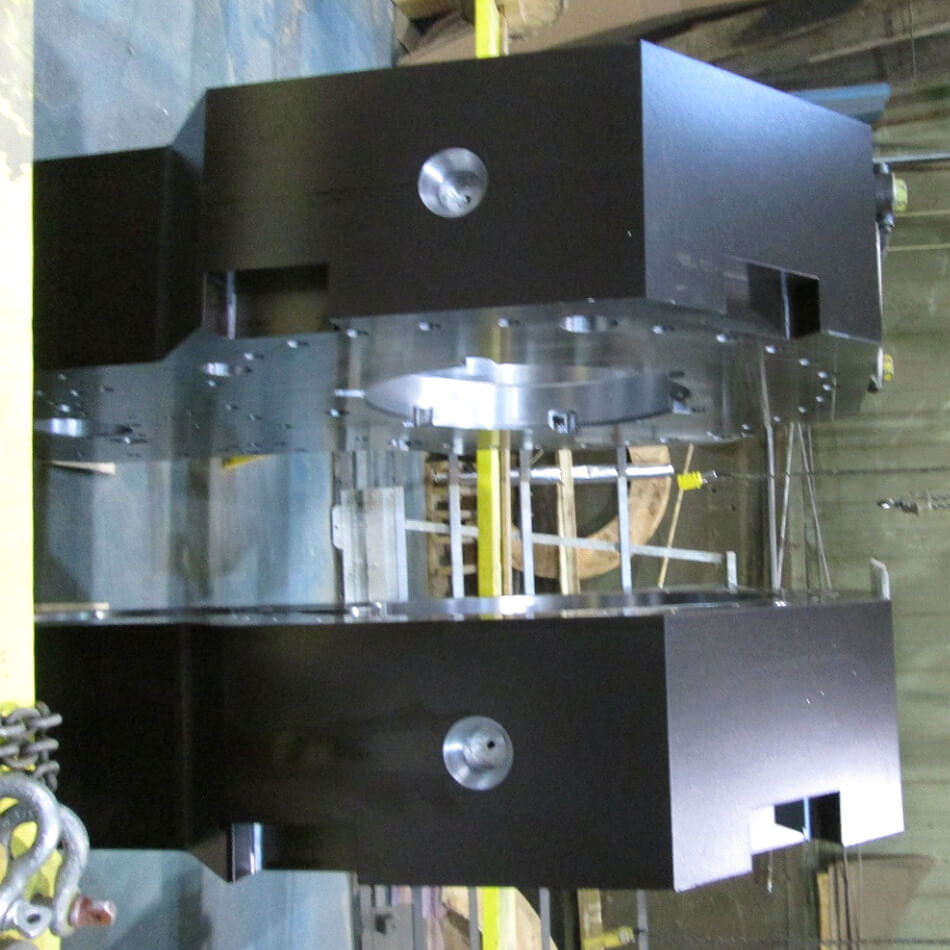

Usinage haute précision d’outillage pour moule de pièces aéronautiques

Usinage haute précision pour outillage du secteur automobile

Usinage d’outillage, grand format, pour banc d’essai du secteur aéronautique

Fabrication et usinage d’outillage du secteur tréfilerie