Que cherchez-vous?

X

Aucun résultat

Recherche en cours ....

Entrez au moins {{MinCars}} caractères

{{result.Name}}

{{result.SubInfo}}

Études de cas

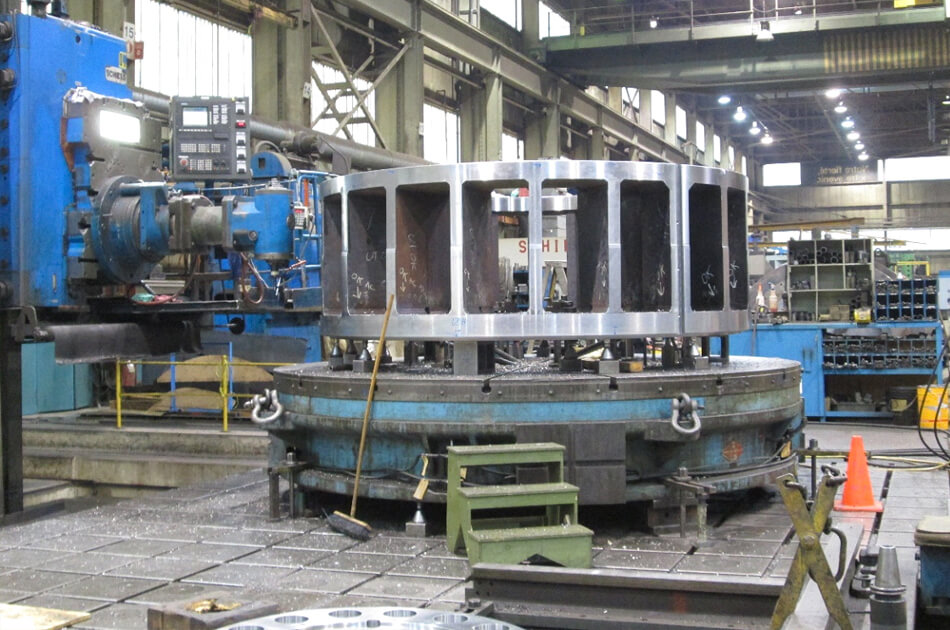

Quelques réalisations

Usinage d’un arbre turbine neuf

Remise à neuf et profilage de grandes directrices (21 000 lbs)

Fabrication et usinage d’un support de palier

Usinage d’un arbre turbine

Remise à neuf d’un arbre générateur

Remise à neuf et test mécanique d’une roue Kaplan

Fabrication et assemblage mécanique d’un «Synchronous Condenser»